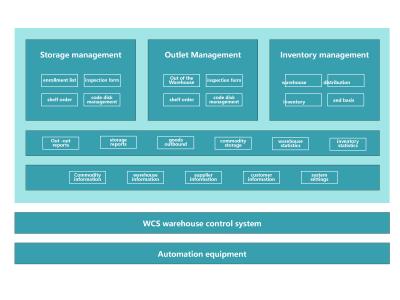

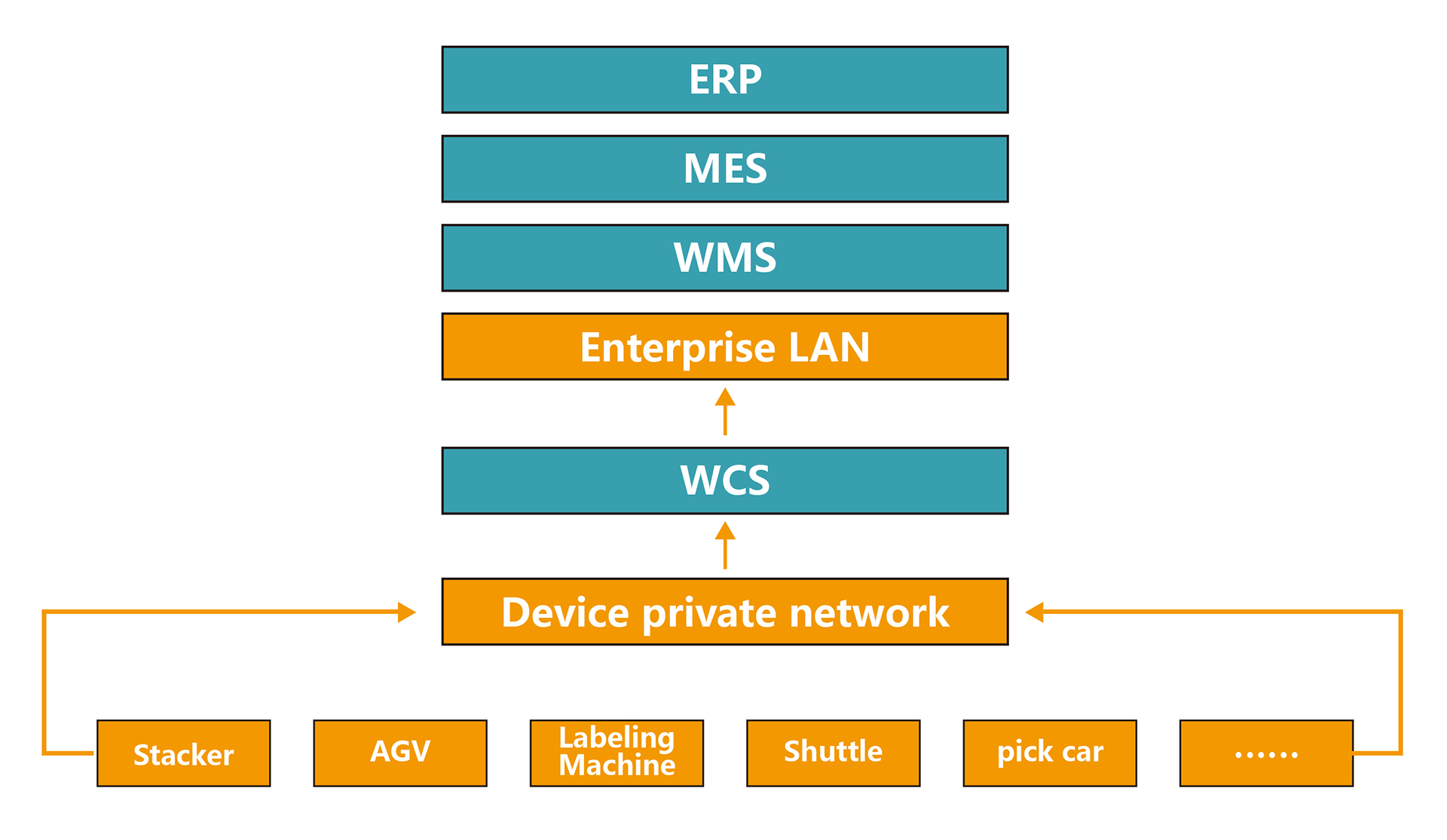

The wcs system is known as: warehouse control system, also called by some in the industry: warehouse equipment scheduling system, wcs system is mainly used in the automated three-dimensional warehouse, is an important part of the automated three-dimensional warehouse. It is an important part of the automated warehouse. It obtains the operational tasks of the wms (warehouse management system) upwards and issues detailed operating instructions to the automated equipment downwards.

Main functions of the wcs system

1. Docking with the system in the warehouse, to achieve information interaction in the warehouse

For the manufacturing industry, the wcs system often needs to dock with the wms warehouse system, mes generation execution system, erp system and other major enterprise management software. wcs system belongs to the lowest execution layer system in the whole enterprise information flow, it needs to get the instructions from the upper system upwards to guide the warehouse operation.

2. Smooth process docking to on-site automation equipment

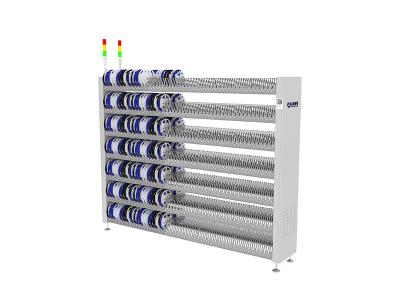

The wcs system is not directly interfaced with the hardware equipment, but through the communication protocol and the underlying PLC of the hardware equipment, and then control the forward and backward movements of the equipment. The wcs system of Nanjing Dalu has been interfaced with hardware equipment such as stacker cranes, four vehicles, AGV trolleys, container trucks, conveying lines, robotic arms, labelling machines, profile detection light curtains, pointing machines, code readers, etc.

3. Warehouse site monitoring, feedback equipment status

The wcs system is equivalent to the warehouse site monitor, it can intuitively and accurately access the state of all hardware equipment in the warehouse, location, warning status, and the implementation of the task. Generally speaking wcs system has a built-in 3D monitoring system, this system can be more intuitive to the warehouse site situation, using the visual form of display in front of the warehouse manager.

4. wcs system security features

For the unmanned warehouse, the most important concern in addition to operational efficiency, is to ensure safety. Safety for the automated warehouse is the most important, wcs system must be in all aspects of functional design attention to ensure the safety of equipment, product safety in the warehouse, equipment anti-touch measures, path planning and other issues, all aspects of the automated three-dimensional warehouse to improve the level of safety.

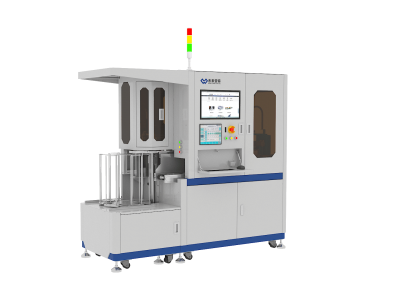

(1) Input devices: PC, sensors, switches and buttons, etc.

(2) Output equipment: PC, servo motor, electric cylinder, speed control motor

(3) Operating environment: Mitsubishi PLC (5U)

(4) Communication network equipment: industrial switch (wired network)

2.2、Support software

(1) Program programming and interface development software: VS2019, SQL, Mitsubishi GX Work3 and EasyBuilder Pro

2.3. Installation

(1) Install the PLC on the storage equipment and power it up.

(2) Open GX Work3 on the PC, run the corresponding project program, connect the PLC via a special communication cable, and download the compiled program to the Mitsubishi PLC on the programming software.

(3) Software installation test: After the complete assembly of the equipment, this PLC program needs to be used in conjunction with the warehouse management system software for testing.