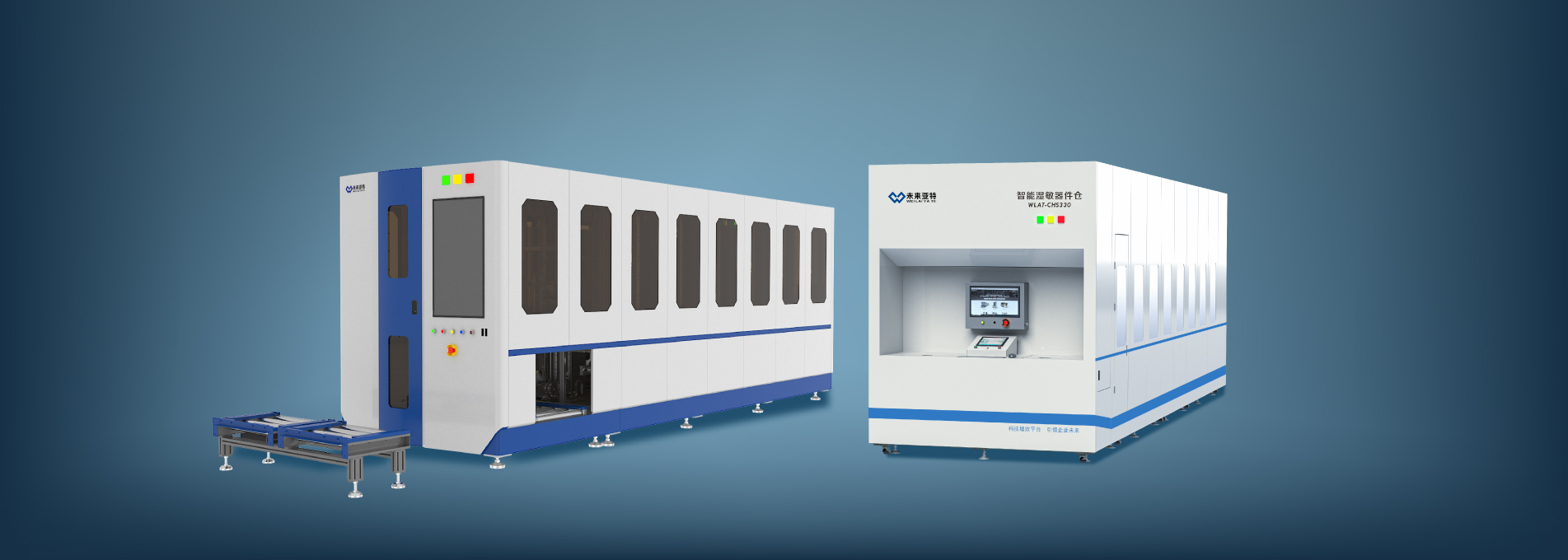

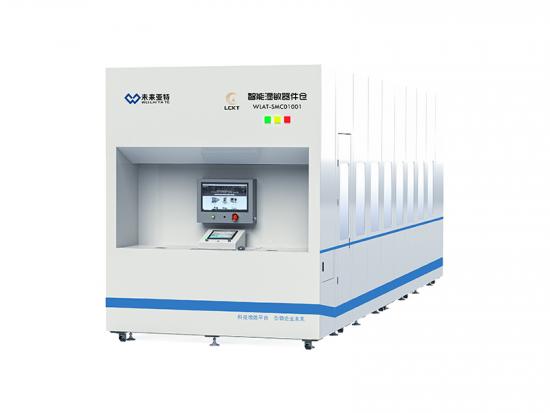

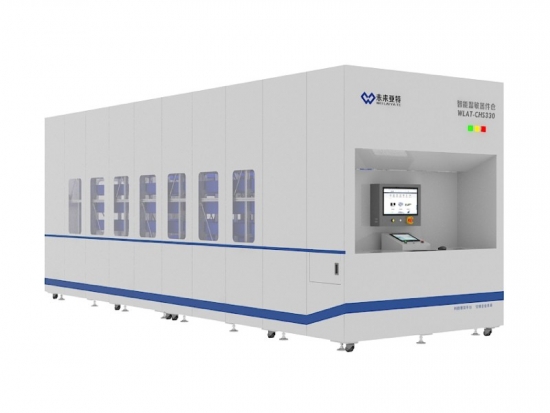

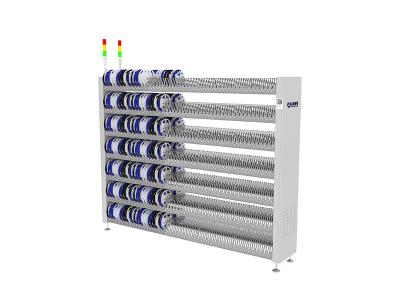

Intelligent moisture sensitive device storage solutions

Solving the storage needs of precision electronic components

-

Intelligent management

First-in, first-out principle, dummy-proof and error-proof, with traceability

Intelligent management

First-in, first-out principle, dummy-proof and error-proof, with traceability

-

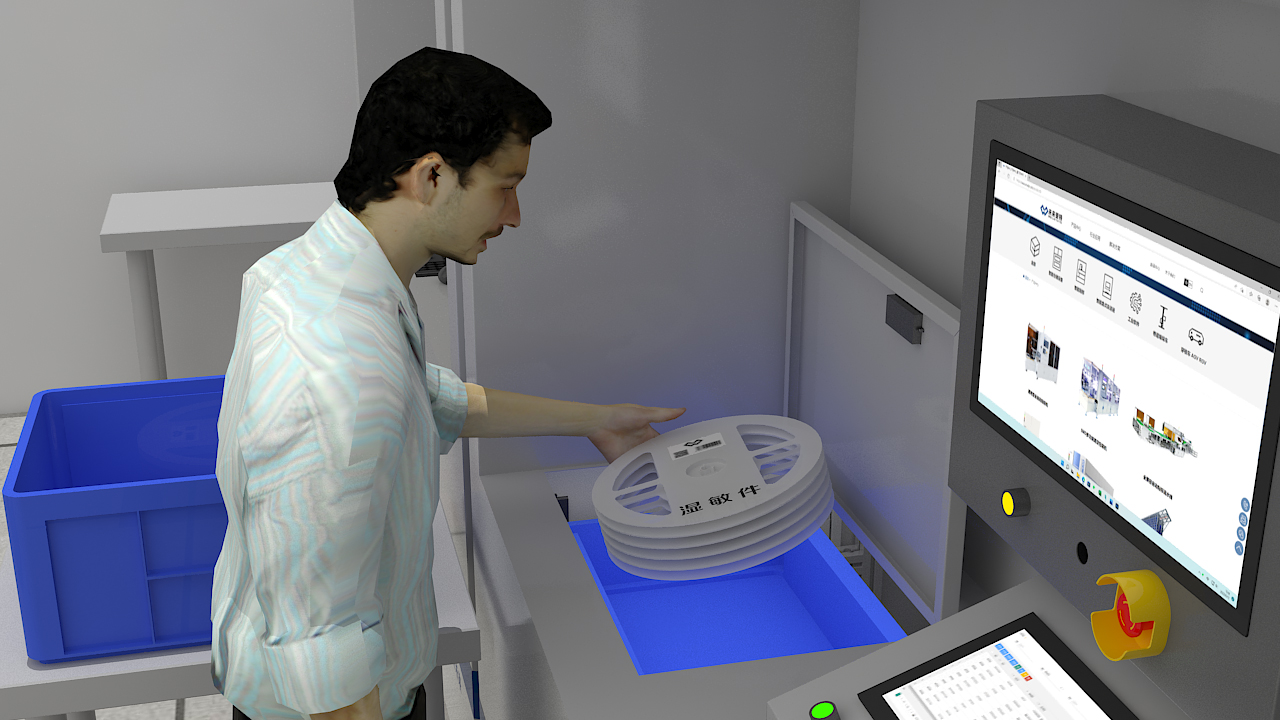

1、Sweep code associationSweeping the material into the bin and Scan the code, put it into the bin, and associate the product code with the bin barcode;

1、Sweep code associationSweeping the material into the bin and Scan the code, put it into the bin, and associate the product code with the bin barcode; -

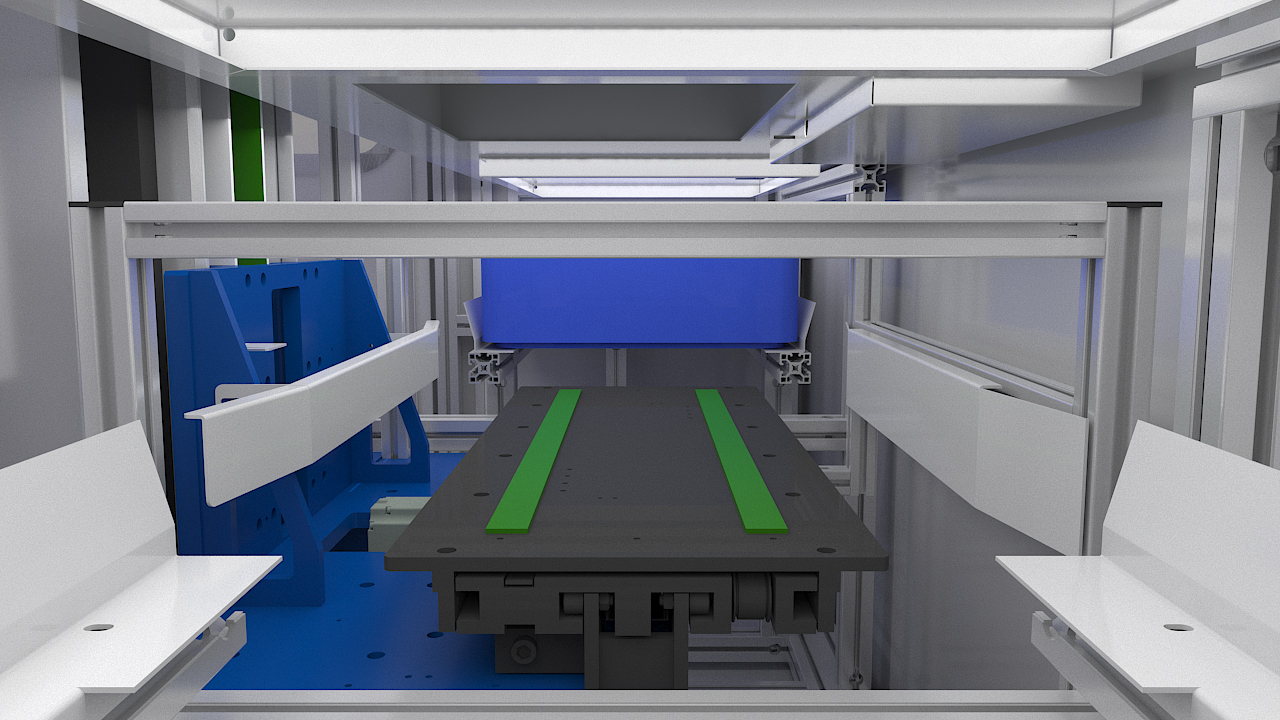

2、InboundThe aisle stacker crane forks the material box and sends it to the storage position designated by the system;

2、InboundThe aisle stacker crane forks the material box and sends it to the storage position designated by the system; -

3、Placement of materialsArriving at the designated storage position, the aisle robot arm is precisely positioned and the material is placed;

3、Placement of materialsArriving at the designated storage position, the aisle robot arm is precisely positioned and the material is placed;

-

4、DischargeWhen leaving the warehouse, the aisle stacker crane forks the bins and sends them to the outgoing conveyor;

4、DischargeWhen leaving the warehouse, the aisle stacker crane forks the bins and sends them to the outgoing conveyor; -

5、Fetching materialThe operator picks up the product at the outbound end and unlinks the product code from the bin barcode;

5、Fetching materialThe operator picks up the product at the outbound end and unlinks the product code from the bin barcode; -

6、Cycle operationAccording to the customer's demand, send the system instruction, so as to cycle operation;

6、Cycle operationAccording to the customer's demand, send the system instruction, so as to cycle operation;

Functional features

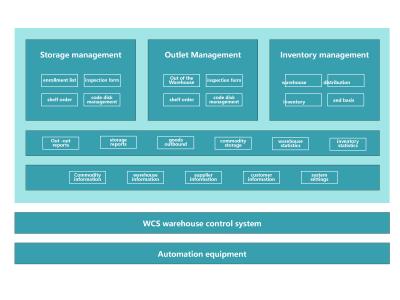

l The system can be docked with any WMS, ERP, MES, etc.

l First in, first out, to achieve accurate management of materials

l Equipped with temperature and humidity management module, which can manage materials at a constant temperature to ensure the quality of materials

l 100% accuracy rate with dummy-proofing and error-proofing throughout the process

l Adopt unique code, material traceability

l Intelligent operation, reducing labour and improving efficiency

l Simple and easy to operate, only 1 person is needed

In production use, the system can record each use of the order, use time, analysis of loss costs, etc. Work order preparation, secondary sorting of end materials, sorting of end materials back to storage, asset inventory and other links, using intelligent storage equipment instead of personnel operation, greatly improving efficiency.

|

|

Scope of application

Used in the electronic components industry, mainly in SMT factories

| Parameters | SMT Intelligent Warehouse (Humidity-sensitive) |

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Loading and

Unloading Buffer

|

Two access for loading and unloading materials |

| Efficiency | 12s/box for storage; 12s/box for retrieval |

| Capacity | 200~500 storage location(Can be customized according to customer requirements) |

| Power Supply | AC220V(25A) |

| Air Pressure | 0.5MPa clean compressed air (overseas customers can customize according to actual power supply voltage) |

|

Dimensions

(L*W*H mm)

|

8000*2200*2800(length and height can be customized on-site) |

|

Intelligent

Configuration

|

Temperature and humidity detection module / uninterrupted power supply module / in and out of warehouse visual code reading and error prevention module |

| Other | Suitable for precision electronic components or other valuable materials |

| Remarks | —— |