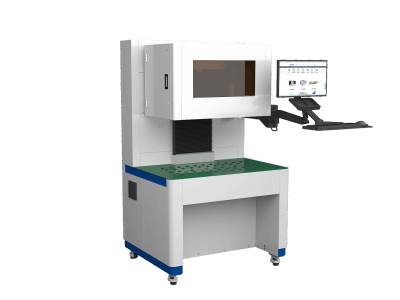

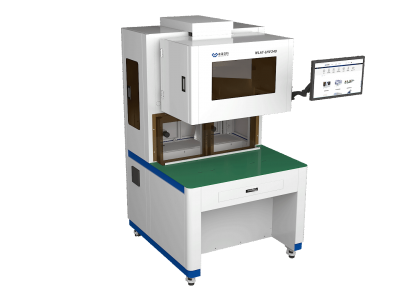

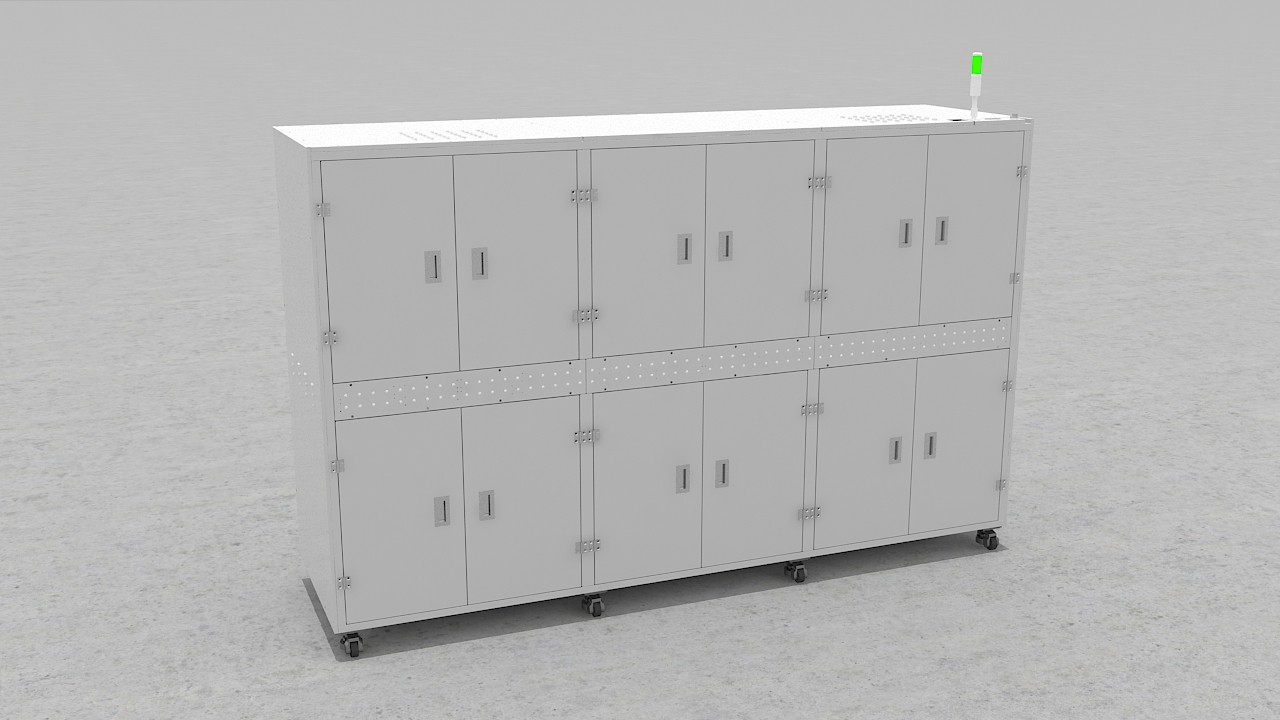

Intelligent stencil storage Cabinet solutions

Fast receipt, dispatch and retrieval of materials

-

1、Storage of materialsWhen storing materials, just put the stencil into the corresponding position according to the lighted prompt;

1、Storage of materialsWhen storing materials, just put the stencil into the corresponding position according to the lighted prompt; -

2、Upload systemThe sensor detects the material, uploads it to the system, and the system indicates that the material is successfully stored;

2、Upload systemThe sensor detects the material, uploads it to the system, and the system indicates that the material is successfully stored; -

3、Fetching materialWhen picking up the material, the light below the position to be The light below the position to be picked up will light up, take away The light at the position to be picked up will light up, take away the material, the system prompts to pick up the material successfully;

3、Fetching materialWhen picking up the material, the light below the position to be The light below the position to be picked up will light up, take away The light at the position to be picked up will light up, take away the material, the system prompts to pick up the material successfully;

Functional features

l The system can be docked with any WMS, ERP, MES, etc.

l The system can be connected to any WMS, ERP, MES, etc.

l Supports multiple pick-ups

l Simple operation, 1 person is equivalent to 4 people

Scope of application

Used in the electronic components industry, mostly in SMT factories, for storage and dosing of electronic components (tray, bag, box are compatible), for line side bin storage, picking up material, picking up material according to BOM, picking up material in order according to station table. It is also used in various material management scenarios with large SKU's, large quantities and frequent picking up and storage.

| Parameters | Intelligent stencil storage Cabinet |

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

material

|

Compatible with tray, bag and box materials |

|

Error prevention

mechanism

|

inductive/ QR code |

| Storage capacity | 76 steel mesh storage; 2 layer steel mesh cabinet |

| Power Supply | AC220V(3A)(Overseas users can customize according to the actual power supply voltage) |

|

Dimensions

(L*W*H mm)

|

2996*820*1934 |

| Other | Hinge double door |