X-Ray Intelligent Counting Solutions

Accurate and efficient solution to the material "inventory" problem

-

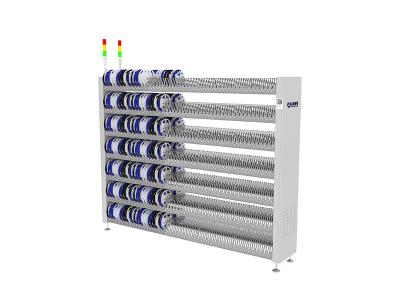

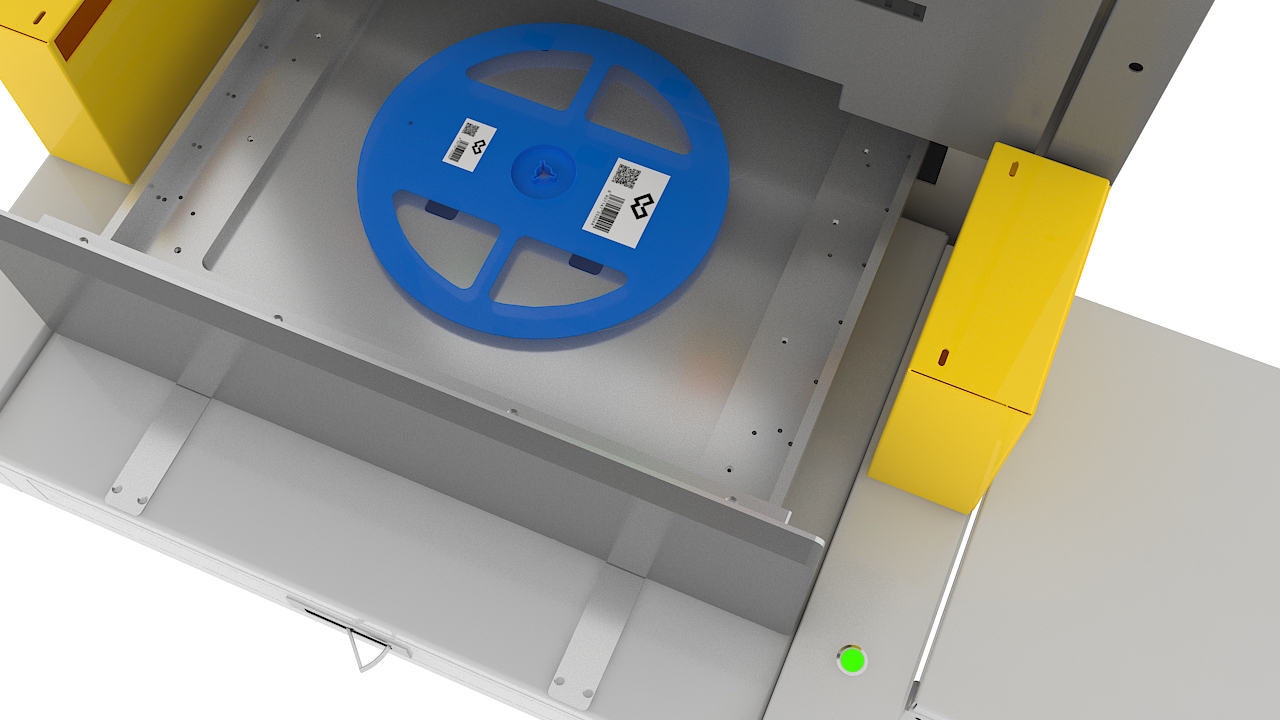

2、 StartAfter start-up, the trays are automatically fed into the material counting area;

2、 StartAfter start-up, the trays are automatically fed into the material counting area; -

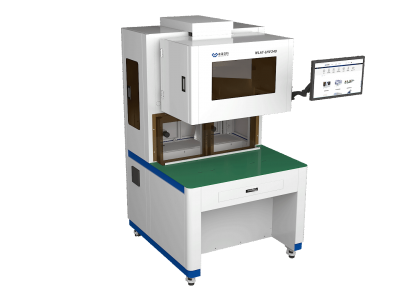

3、Automatic countingSingle station dispensing, manual labelling, thus the cycle;

3、Automatic countingSingle station dispensing, manual labelling, thus the cycle;

l supports 7-15" material, height 8mm-70mm

l system can be interfaced with any WMS, ERP, MES, etc.

l is equipped with dual workstation tooling, waiting for interchangeable operations, 7" can place 4 trays, 13" can place 1 tray

l is fully compatible with online ordering and can be connected to a printer to support offline printing

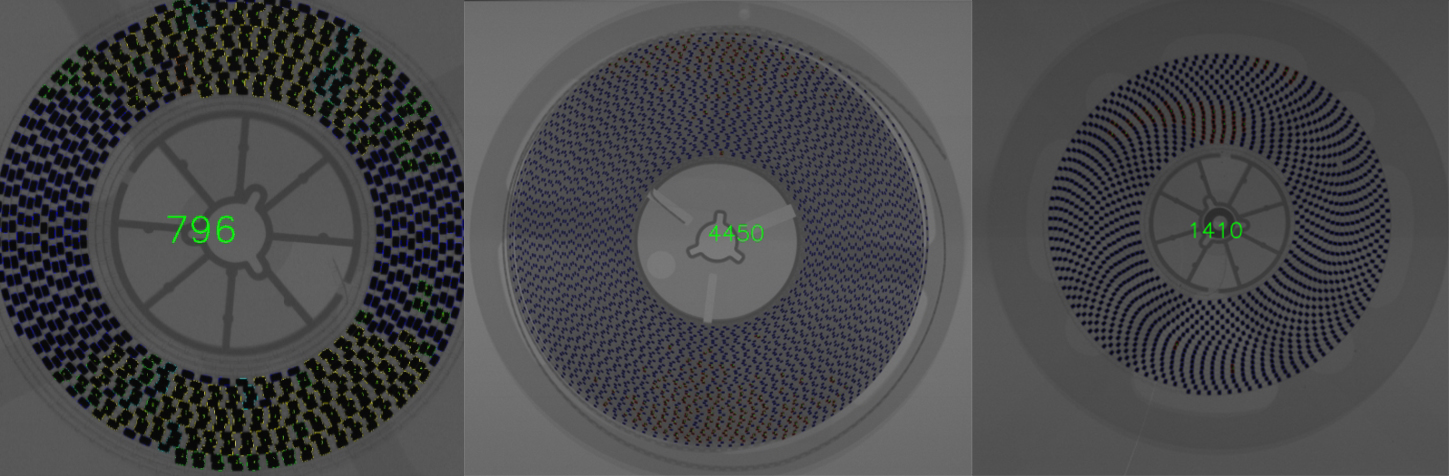

l can count materials with 99.99% accuracy to ensure the accuracy of the material back to the end of the warehouse, lean management of material use and loss.

l is easy to operate and can be operated by 1 person.

Scope of application

Used in the electronic components industry to count the end of SMD pallets with an average accuracy of 99.99% (accuracy varies for different material sizes)

| Parameters | Single station SMT component counter(semi-automatic) |

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Compatible

materials

|

Diameter:7-15or materials of the same size in a flat state; Height:5mm~70mm |

| Efficiency | 480 reels/hour (7” SMD) |

| Accuracy | 99.99% (MIN detectable 01005) |

|

X-ray

configuration

|

17” flat panel detector with 139μm; VJ source 80KV/100W |

| Power Supply | AC220V(10A) |

| Air pressure | 0.5MPa clean compressed air (overseas customers can customize according to the actual local power supply voltage) |

|

Dimensions

(L*W*H mm)

|

1411*927*2048 |

|

Loading and

Unloading

|

Manual loading and unloading: 4 reels/7” at a time, 1 reel/13” and above |

|

Series

Configurations

|

Automatic security access gate; Radiation dose: better than the national standard ≤1uSv/hr |

| Other | Compatible with online material point function, can also be connected to a printer, built-in 1000W industrial camera, offline labeling to prevent errors. |