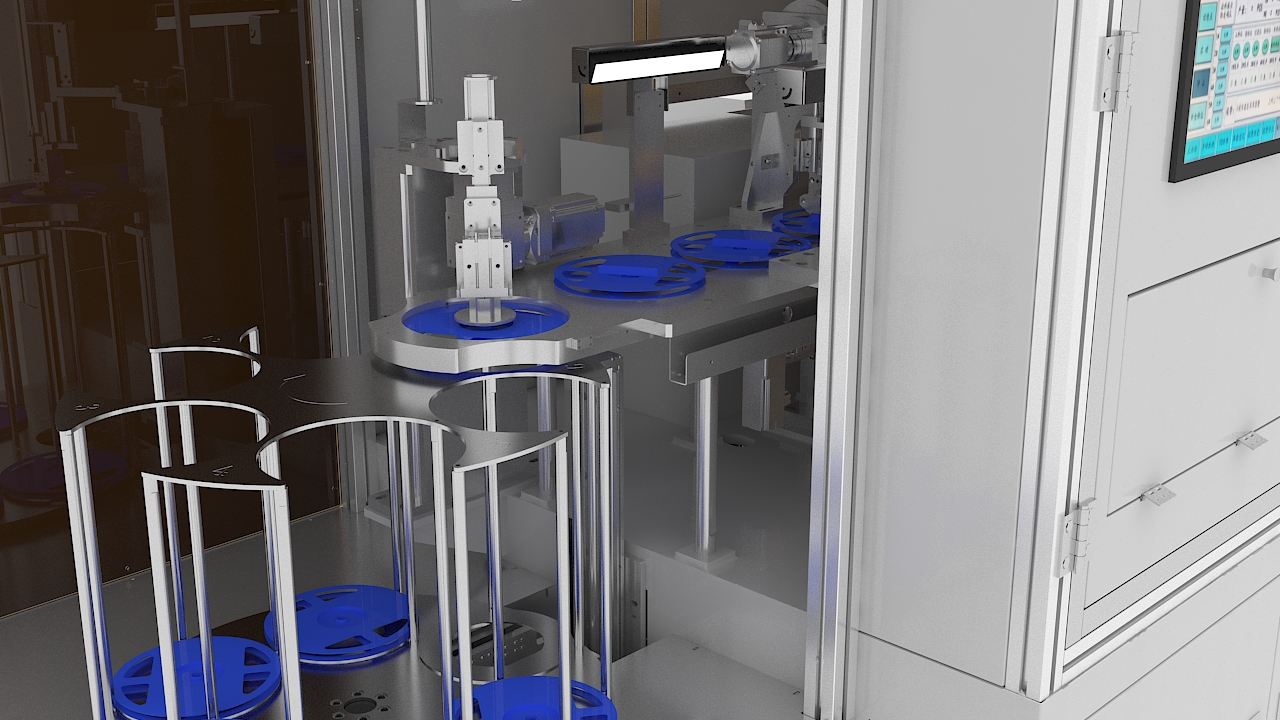

SMD Multifunctional Vacuum Packaging Machine

Solving the storage, packaging and transportation needs of electronic components

-

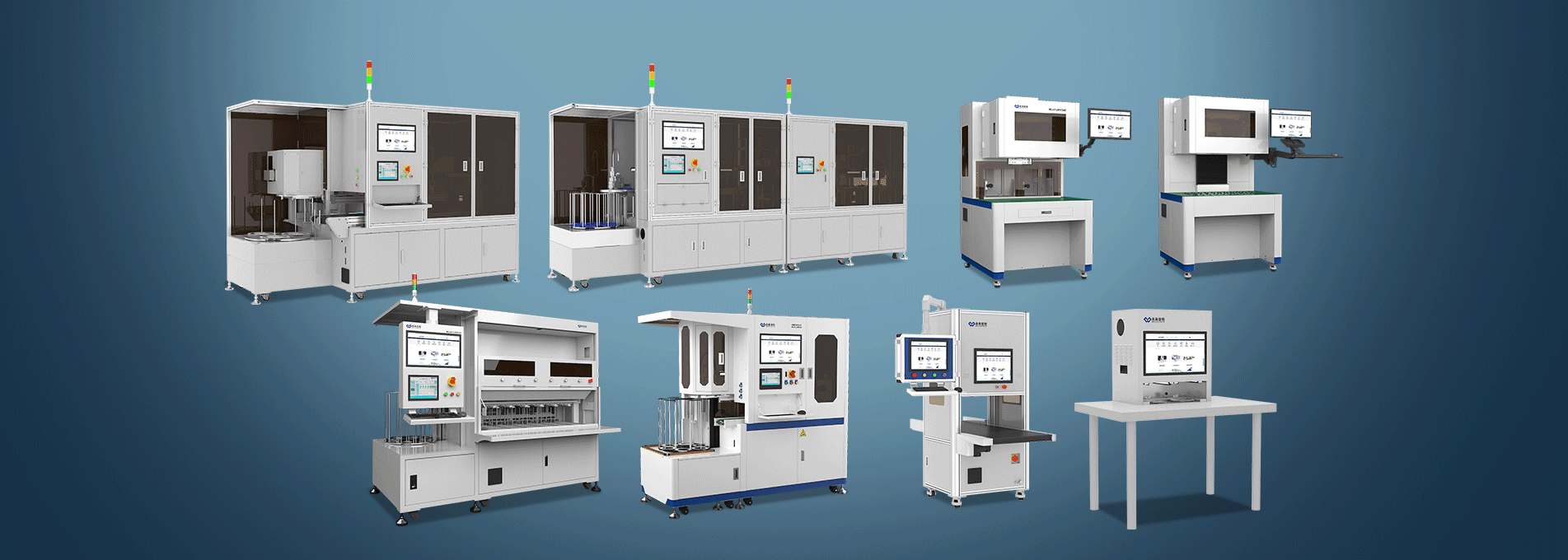

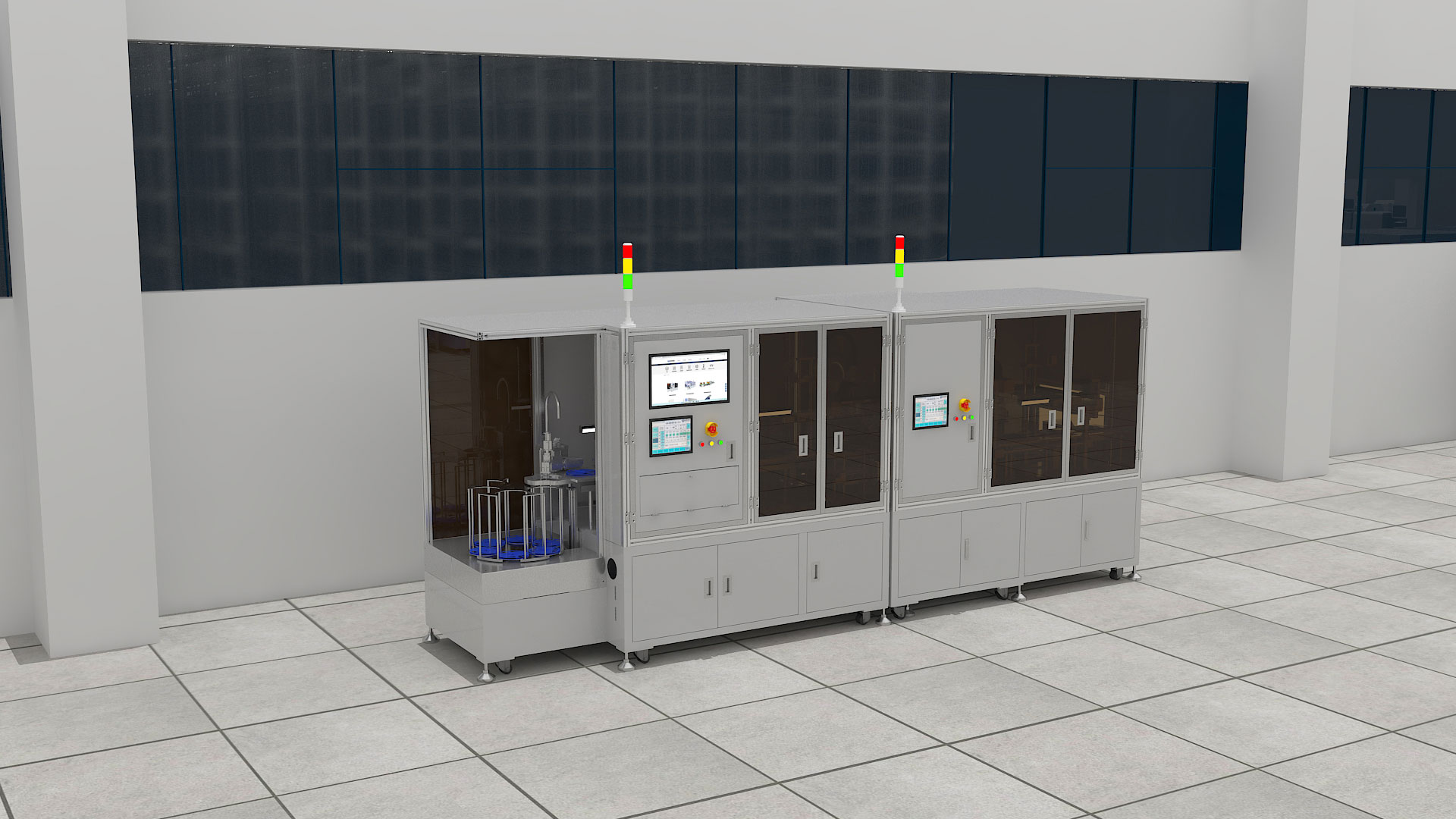

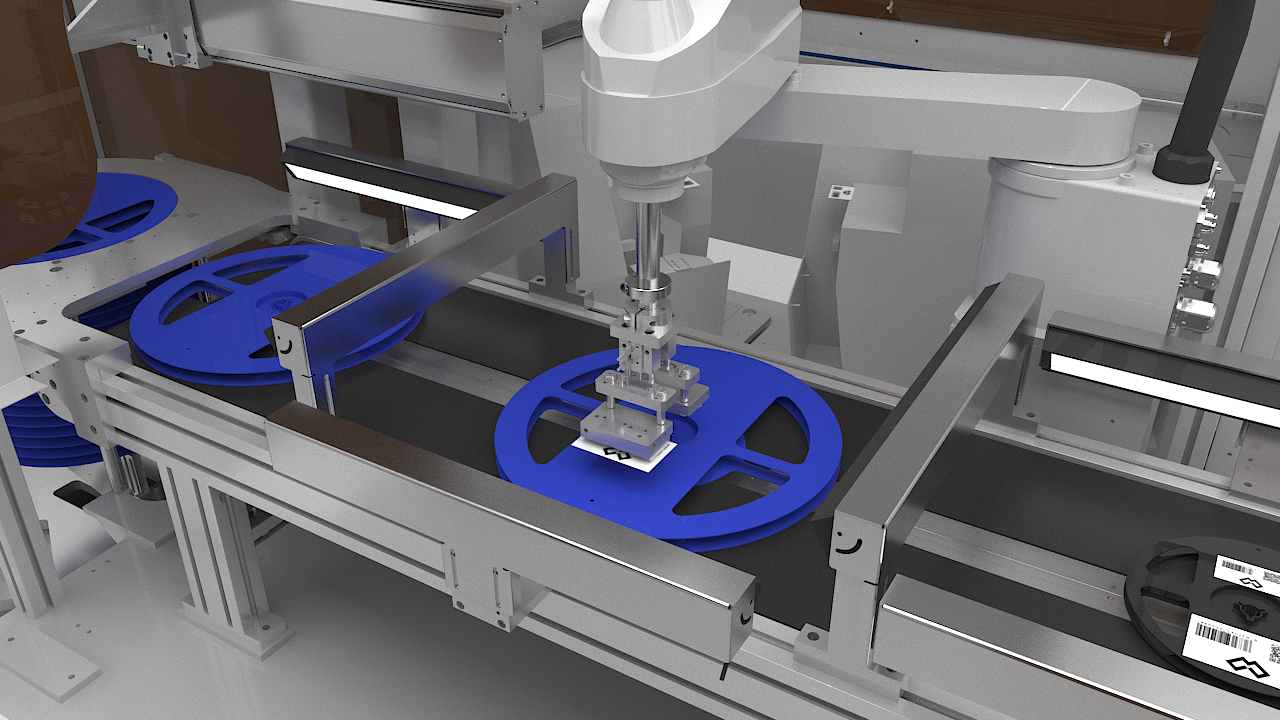

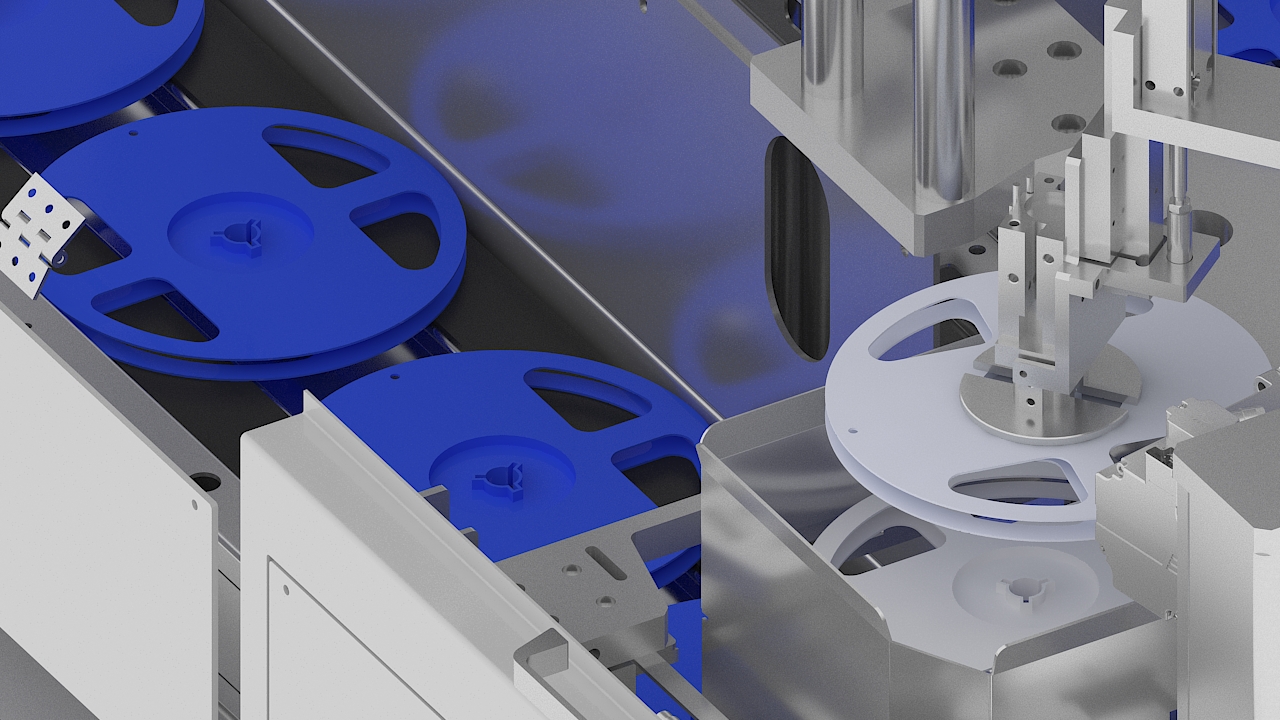

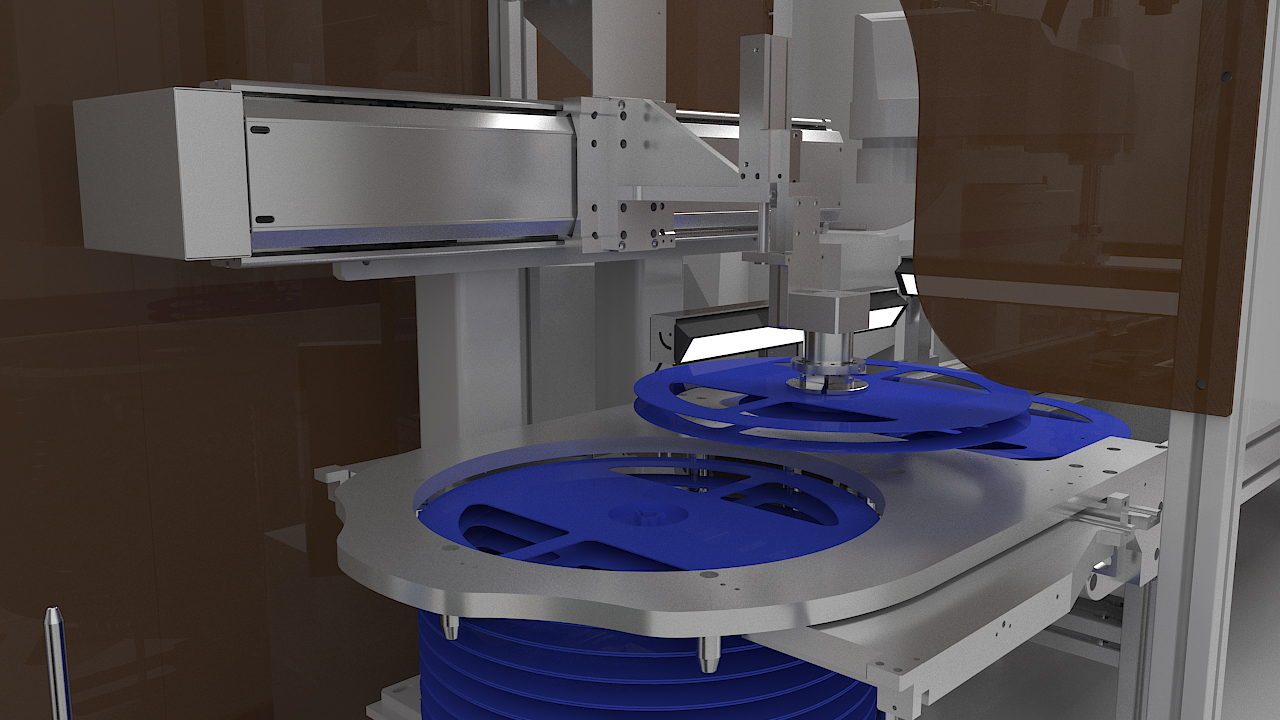

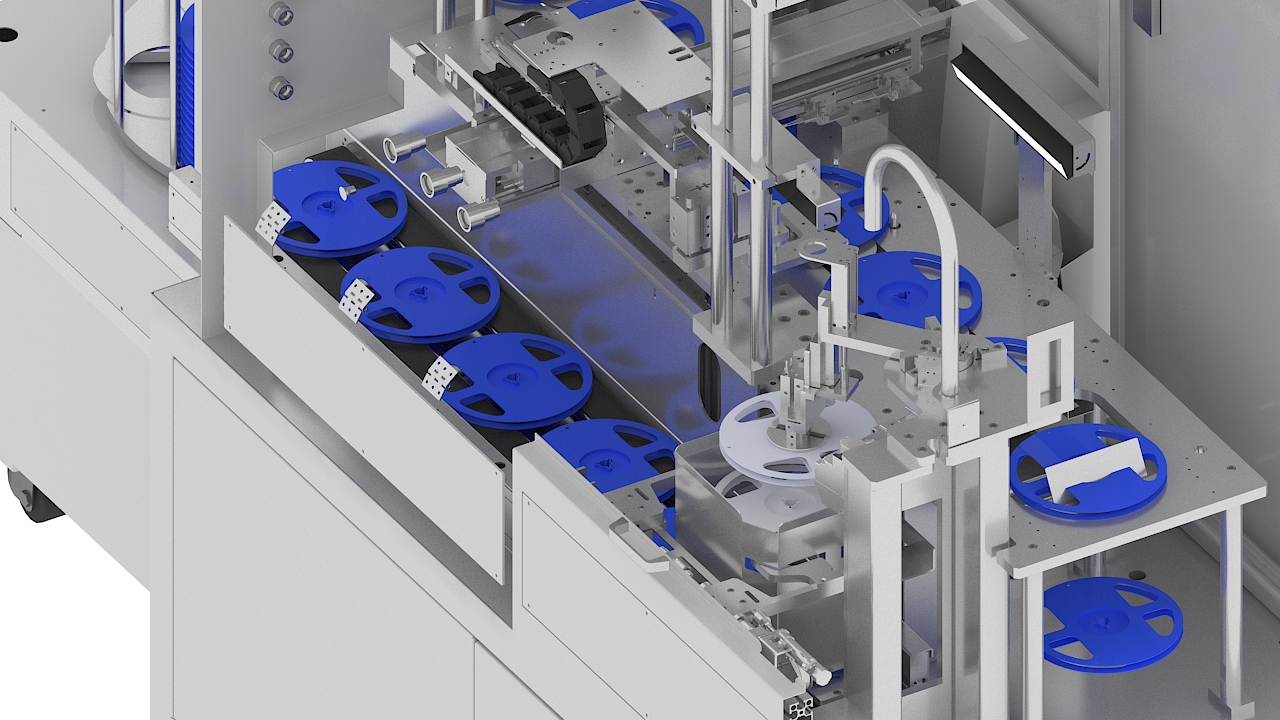

2、Automatic loadingThe loading jacks lift the trays and the jaws carry the trays to the fork conveyor line;

2、Automatic loadingThe loading jacks lift the trays and the jaws carry the trays to the fork conveyor line; -

3、Automatic code readingThe industrial camera locates and reads the The industrial camera locates and reads the The industrial camera locates and reads the pallet and sends it to the WMS system;

3、Automatic code readingThe industrial camera locates and reads the The industrial camera locates and reads the The industrial camera locates and reads the pallet and sends it to the WMS system;

-

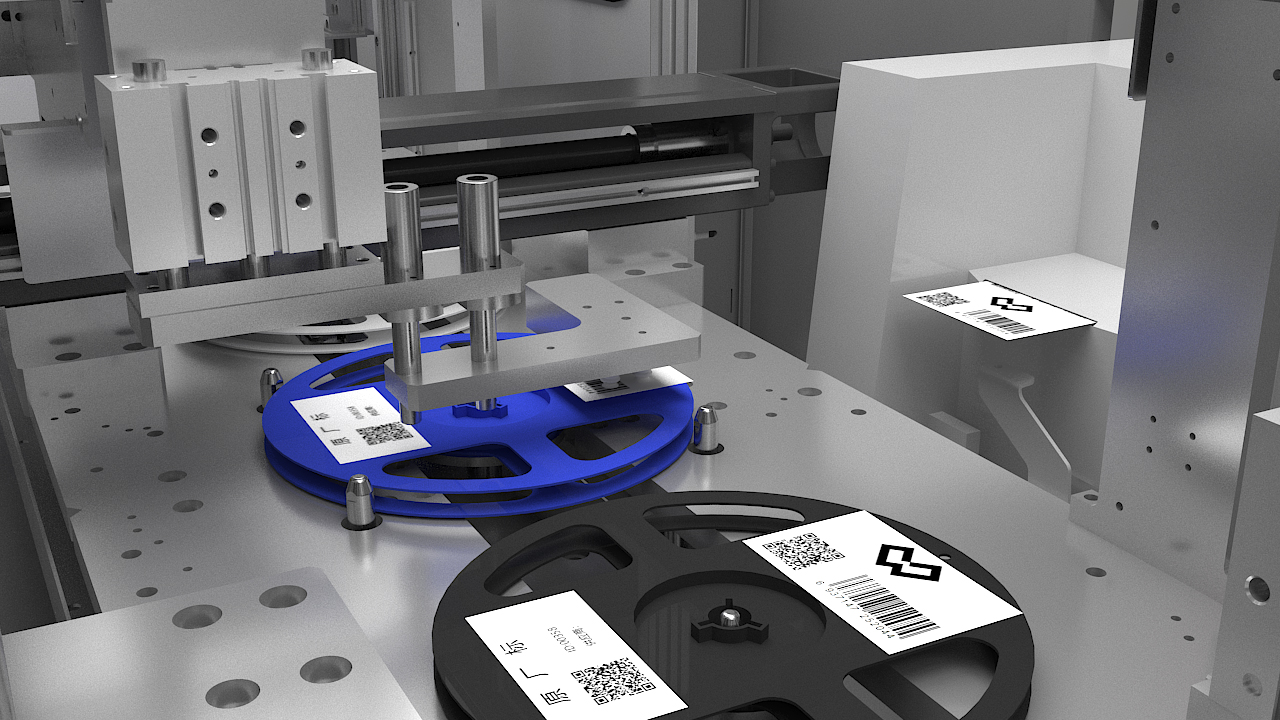

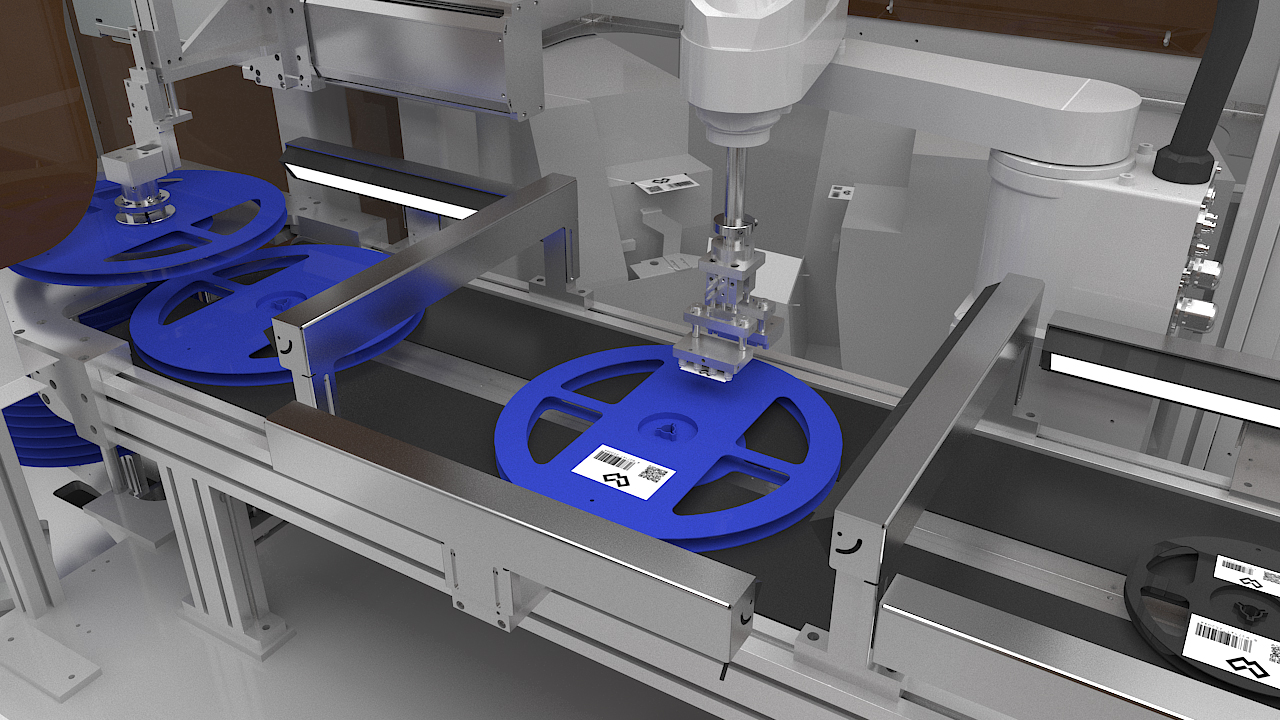

4、Automatic labelingThe material tray is transported to the labeling station, and the labeling mechanism will label the material tray;

4、Automatic labelingThe material tray is transported to the labeling station, and the labeling mechanism will label the material tray; -

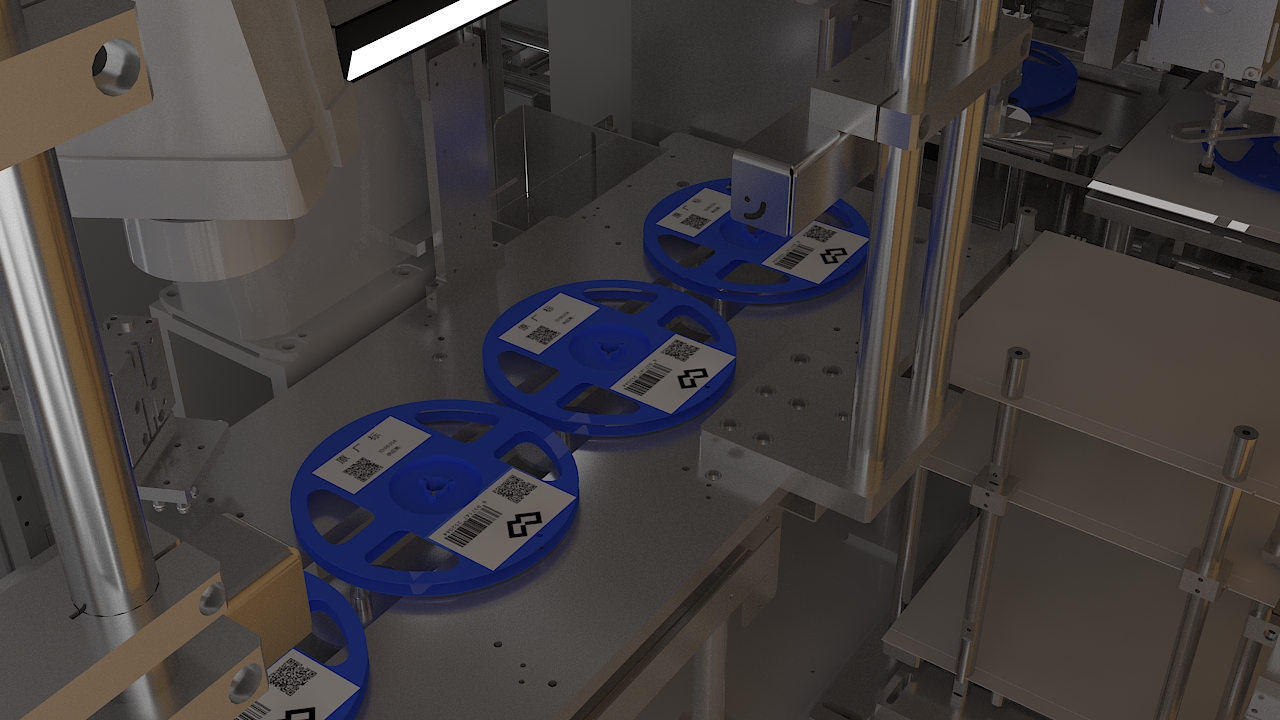

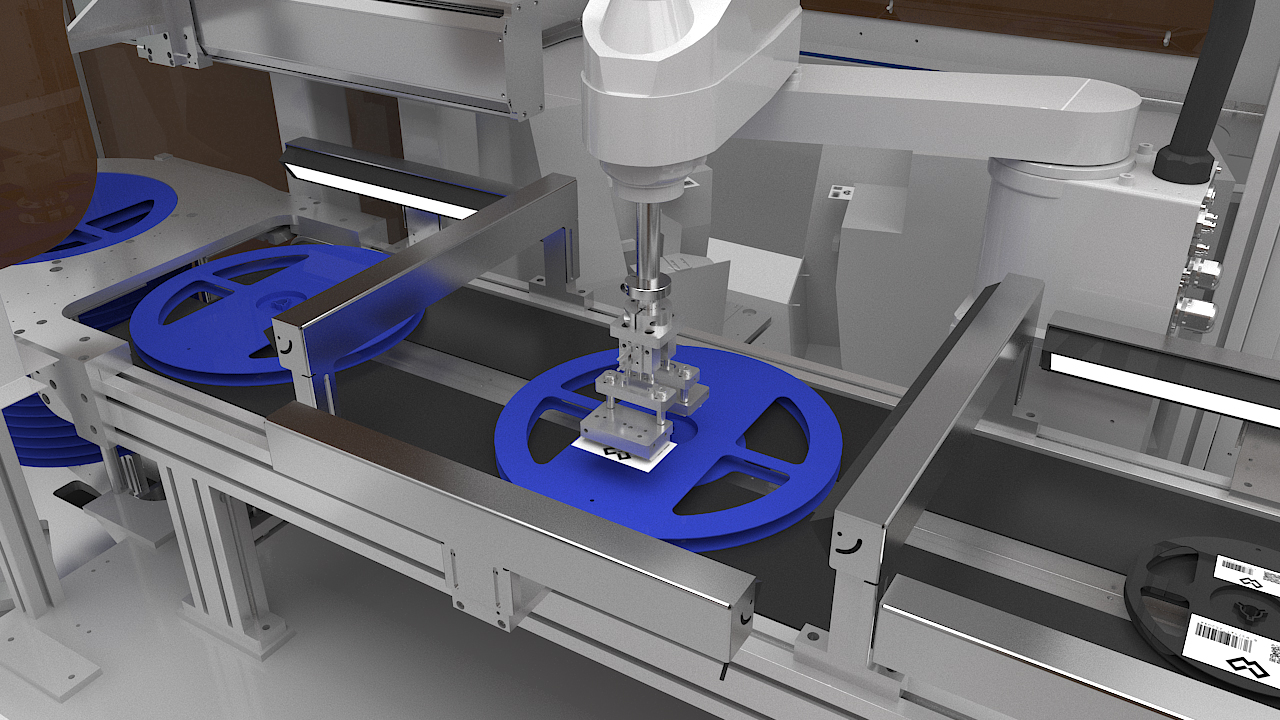

5、Automatic reviewThe camera identifies the label of the material tray and sends the result to the system;

5、Automatic reviewThe camera identifies the label of the material tray and sends the result to the system; -

6、Automatic material dischargingQualified material tray is placed in desiccant and moisture sensitive card station, unqualified is rejected;

6、Automatic material dischargingQualified material tray is placed in desiccant and moisture sensitive card station, unqualified is rejected;

-

7、Bagging and vacuumingBag and heat seal the moisture-sensitive card, desiccant and material tray;

7、Bagging and vacuumingBag and heat seal the moisture-sensitive card, desiccant and material tray; -

8、Labeling and reviewLabeling the bagged products, the camera identifies the labels, and the review results are sent to the mid-ticket machine system;

8、Labeling and reviewLabeling the bagged products, the camera identifies the labels, and the review results are sent to the mid-ticket machine system; -

9、Automatic stacking and dischargingAutomatic stacking and discharging of qualified products, rejection of unqualified products to the NG port;

9、Automatic stacking and dischargingAutomatic stacking and discharging of qualified products, rejection of unqualified products to the NG port;

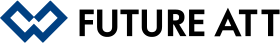

Functional features

l for 7" pallets

l for 7" pallets

l system can be interfaced with any WMS, ERP, MES etc.

l is equipped with desiccant and moisture sensitive card, vacuum packing, high efficiency and good air tightness

l supports double labeling (double labeling of trays and double labeling of bags)

l automatic scanning, labeling, review, placing desiccant, moisture sensitive card, bagging, vacuum packing, review, batch stacking and discharging, etc. multi-functional integrated service

l is equipped with four 2000w pixel industrial cameras for code reading, double checking and positioning, configured with NG channels to meet accuracy requirements

l requires only 1 person to operate

The equipment is a one-stop service from labeling, review, placing desiccant, moisture sensitive card, bagging, vacuum packing, review, batch stacking and discharging, etc., which solves the needs of labeling, storage, transportation and other multi-field applications faced by customers in the daily production and sales process, ensuring product quality and improving product competitiveness.

|

|

Scope of application

For fully automatic labelling of electronic components (resistive original 7" ~ 13" SMD pallets) to customers. Can be used for original manufacturers and distributors.

| Parameters | SMD packing machine |

|

Integration

System

|

system can be integrated with any WMS, ERP, MES, etc. |

|

Material Loading

&unloading

|

180 reels/loading reel; 25 reels/unloading reel |

|

Compatible

material

|

Compatible with 7-13 inch materials. |

| Efficiency | 8~12s/pcs |

| Configuration | 4 industrial cameras with 1000w pixel resolution (reading, positioning, and double-checking) |

|

Power Supply

/Frequency

|

Power supply:AC220V (16A) (can be customized according to the actual power supply voltage of the country of use);frequency: 50HZ. |

| Air pressure | Air pressure: 0.5-0.7Mpa, flow rate: 120L/min. |

|

Dimensions

(L*W*H mm)

|

4850*1650*1900 |

| Sorting Optional | sorting by orders/ optional integration with automatic packging equiment |

| Reading Camera | Field of view:180mm*240mm |

| Reading Efficiency | ≤600ms |

| Other | Only requires 1 person. |