Exhibition News丨Future Att made a wonderful appearance in Chongqing Expo

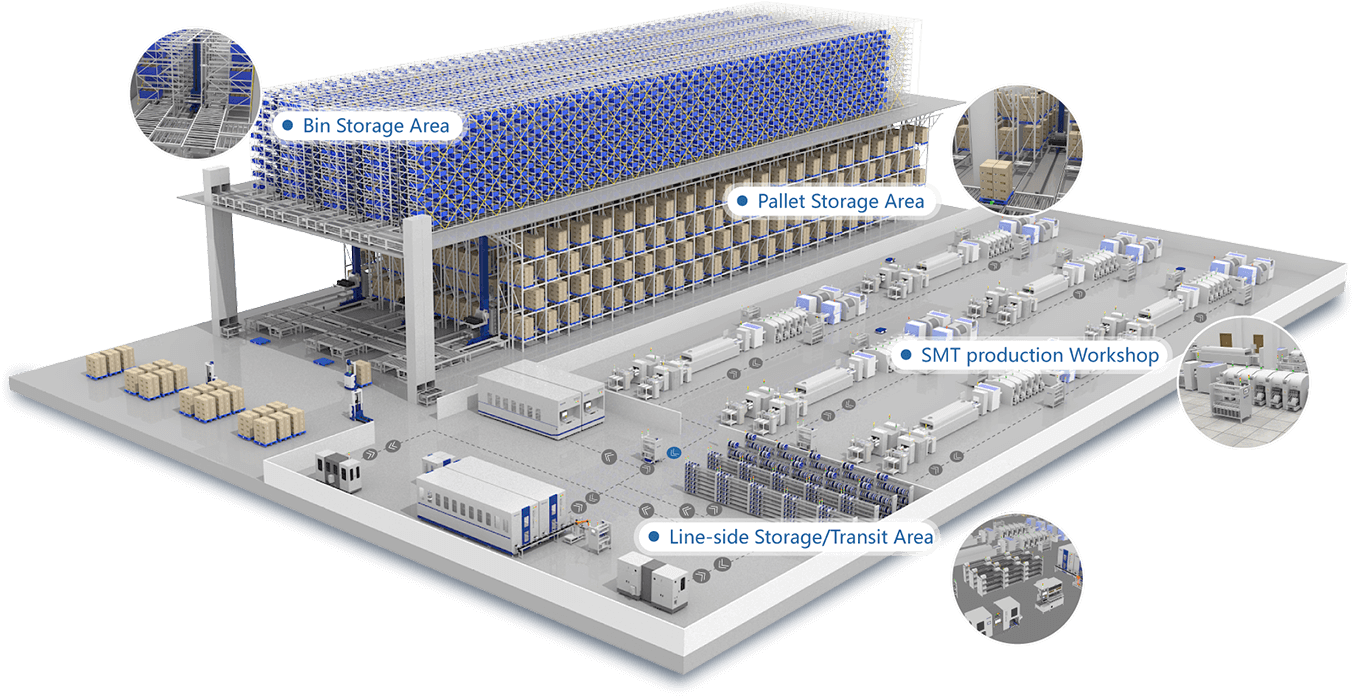

On May 10th, the 5th Global Semiconductor Industry and Electronic Technology (Chongqing) Expo was grandly opened in Chongqing International Expo Center, with 350 exhibitors, w carrying extremely advantageous intelligent electronic material racks, X-Ray intelligent pointing machine , Vertical receipt machine, intelligent picking truck and other intelligent products were exhibited at booth N2-T156, providing customers with customized intelligent storage overall solutions. The overall solution for intelligent storage provided includes intelligent products such as SMT intelligent warehouse series, X-Ray intelligent pointing machine series, intelligent electronic material rack series, intelligent labeling machine series, etc., and is constantly upgrading new products, new technologies, and new Craftsmanship promotes the development of the industry and at the same time helps enterprises to efficiently and powerfully expand target customers and meet customer needs in different fields in the industry. At the exhibition site, by analyzing customer needs, explaining the operation process and functional characteristics of the equipment, and making wonderful operation demonstrations, many customers stopped to visit. As a professional SMT intelligent warehousing overall solution provider, Future Att will provide production-oriented full-process factory intelligent warehousing solutions , from supplier incoming materials, allocation, warehouse transfer, material delivery, material picking, tailings back to the warehouse, etc. , Real-time docking system, making factory material management more efficient, accurate and convenient. SMT Intelligent automatic warehouse It adopts the industry-leading new generation of SMT dual-arm intelligent storage system technology, including visual intelligent avoidance, and realizes synchronous drive through the synchronous operation of the two motors, realizing simultaneous operation of both arms, waiting for entry and exit, and digital management from entry to exit. Reduce the error rate, and realize the safe, flexible, accurate and efficient picking and distribution process operation in an integrated and flexible manner. Double station SMT X-ray counter (semi-automatic) Compatible with 7-15 inch material trays, set double-station mode, the system quickly reads codes, counts materials, one in and one out, counts materials when preparing materials, and works in turns to improve work efficiency, and does not require on-site modification, enabling rapid deployment , Flexible docking production. SMT component storage Mobile rack The wireless intelligent picking vehicle cooperates with the AGV trolley to complete the automatic inbound and outbound operations, flexibly docking with the conveyor line, and quickly send and receive materials according to the light indication, reducing the action of scanning material labels out of the warehouse, responding to the beat of the line side warehouse, and improving...

Read More